Lem Epoxy is often a type of adhesive which is noted for its solid bonding Qualities and flexibility. It's a two-section adhesive, consisting of a resin along with a hardener, which must be combined alongside one another in an effort to activate the bonding process. After blended, Lem Epoxy types a robust, durable bond that is certainly immune to heat, drinking water, and chemical compounds. This makes it a great option for a variety of applications, from family repairs to industrial initiatives.

Lem Epoxy is accessible in a number of formulations, which include speedy-setting and gradual-setting alternatives, together with distinctive viscosities to suit different applications. It can be used to bond an array of supplies, such as metal, wood, plastic, glass, and ceramics. This can make it a flexible adhesive which might be useful for a variety of jobs, from fixing broken house objects to generating intricate crafts and jewelry. Lem Epoxy is additionally obtainable in numerous colors, rendering it quick to locate a formulation that matches the color from the materials remaining bonded.

Tips on how to Use Lem Epoxy

Applying Lem Epoxy is relatively clear-cut, but it's important to Adhere to the maker's Guidelines cautiously so that you can obtain the most effective results. The initial step is to organize the surfaces that should be bonded by cleaning them comprehensively to get rid of any Dust, grease, or other contaminants that can interfere With all the bonding process. When the surfaces are thoroughly clean and dry, the next phase is To combine the resin and hardener alongside one another in the proper proportions. This tends to generally be finished by squeezing equal amounts of Each individual element on to a disposable area, such as a bit of cardboard, after which you can mixing them together with a small adhere or spatula.

Once the resin and hardener have already been carefully blended, they need to be applied to the surfaces which have been to become bonded. It is necessary to operate immediately at this stage, as Lem Epoxy features a constrained Performing time right before it commences to set. The adhesive ought to be applied evenly to the two surfaces, and afterwards The 2 surfaces need to be pressed alongside one another firmly to ensure a great bond. It is vital to hold the surfaces in place till the adhesive has established, which could just take anywhere from a few minutes to a number of hours, with regards to the formulation of Lem Epoxy being used.

Benefits of Lem Epoxy

Lem Epoxy provides a number of benefits which make it a well-liked choice for bonding applications. One of the most important benefits of Lem Epoxy is its power and durability. At the time cured, Lem Epoxy varieties a bond that is certainly resistant to warmth, drinking water, and chemicals, rendering it appropriate for use in a wide range of environments. This can make it a great choice for apps exactly where a solid, prolonged-Long lasting bond is needed.

An additional good thing about Lem Epoxy is its versatility. It may be used to bond a wide range of elements, which includes metallic, wood, plastic, glass, and ceramics. This causes it to be a flexible adhesive which can be used for an array of jobs, from family repairs to industrial purposes. Additionally, Lem Epoxy is out there in different formulations to go well with different programs, together with quickly-placing and gradual-setting possibilities, and various viscosities and colors.

Apps of Lem Epoxy

Lem Epoxy has a variety of applications on account of its energy, longevity, and flexibility. It can be used for family repairs, for example correcting damaged ceramics or restoring picket furniture. It's also frequently Utilized in industrial options for bonding steel parts or developing composite products. On top of that, Lem Epoxy is popular within the crafting and jewelry-making industries because of its ability to bond a wide range of materials and its availability in various hues.

A person prevalent software of Lem Epoxy is while in the automotive market, in which it really is used for bonding metallic parts and fixing plastic components. Additionally it is commonly Employed in development for bonding concrete and masonry components. Additionally, Lem Epoxy is commonly Utilized in marine purposes on account of its resistance to water and substances. Total, Lem Epoxy has a wide range of purposes across various industries on account of its strength, longevity, and versatility.

Strategies for Dealing with Lem Epoxy

When working with Lem Epoxy, there are plenty of guidelines that can help ensure the best benefits. It is important to Keep to the company's Directions very carefully in order to attain the most beneficial bond strength and sturdiness. This features preparing the surfaces appropriately by cleansing them thoroughly and mixing the resin and hardener in the correct proportions.

It is additionally important to perform speedily when applying Lem Epoxy, as it's got a restricted Functioning time ahead of it commences to established. This means that it's important to get all the required equipment and elements organized right before mixing the adhesive. In addition, it is important to apply the adhesive evenly to both surfaces and push them together firmly to ensure a good bond.

Protection Safety measures when Working with Lem Epoxy

When Lem Epoxy is a flexible and successful adhesive, it is vital to get correct safety safety measures when employing it. This contains sporting gloves and eye protection when managing the adhesive in an effort to safeguard the pores and skin and eyes from connection with the resin and hardener. It's also crucial to do the job inside a well-ventilated place when using Lem Epoxy so that you can keep away from inhaling any fumes that may be supplied off through the curing process.

Evaluating Lem Epoxy with Other Adhesives

When evaluating Lem Epoxy with other adhesives, there are various elements to consider. Among the list of primary benefits of Lem Epoxy is its strength and sturdiness. The moment cured, it types a bond that is definitely resistant to heat, drinking water, and chemical compounds, rendering it ideal for use in a wide array of environments. In addition, Lem Epoxy is obtainable in various formulations to suit distinct apps, together with quick-environment and sluggish-location options, along with diverse viscosities and colors.

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Nadia Bjorlin Then & Now!

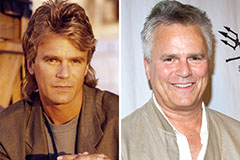

Nadia Bjorlin Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!